UniMole

Mole Drainer

UniMole

Mole Drainer

Key Features

- Minimal disturbance with entry and exit

- Fully floating beam

- Exposed disc to avoid congestion

Key Features

- Minimal disturbance with entry and exit

- Fully floating beam

- Exposed disc to avoid congestion

Key Features

- Minimal disturbance with entry and exit

- Fully floating beam

- Exposed disc to avoid congestion

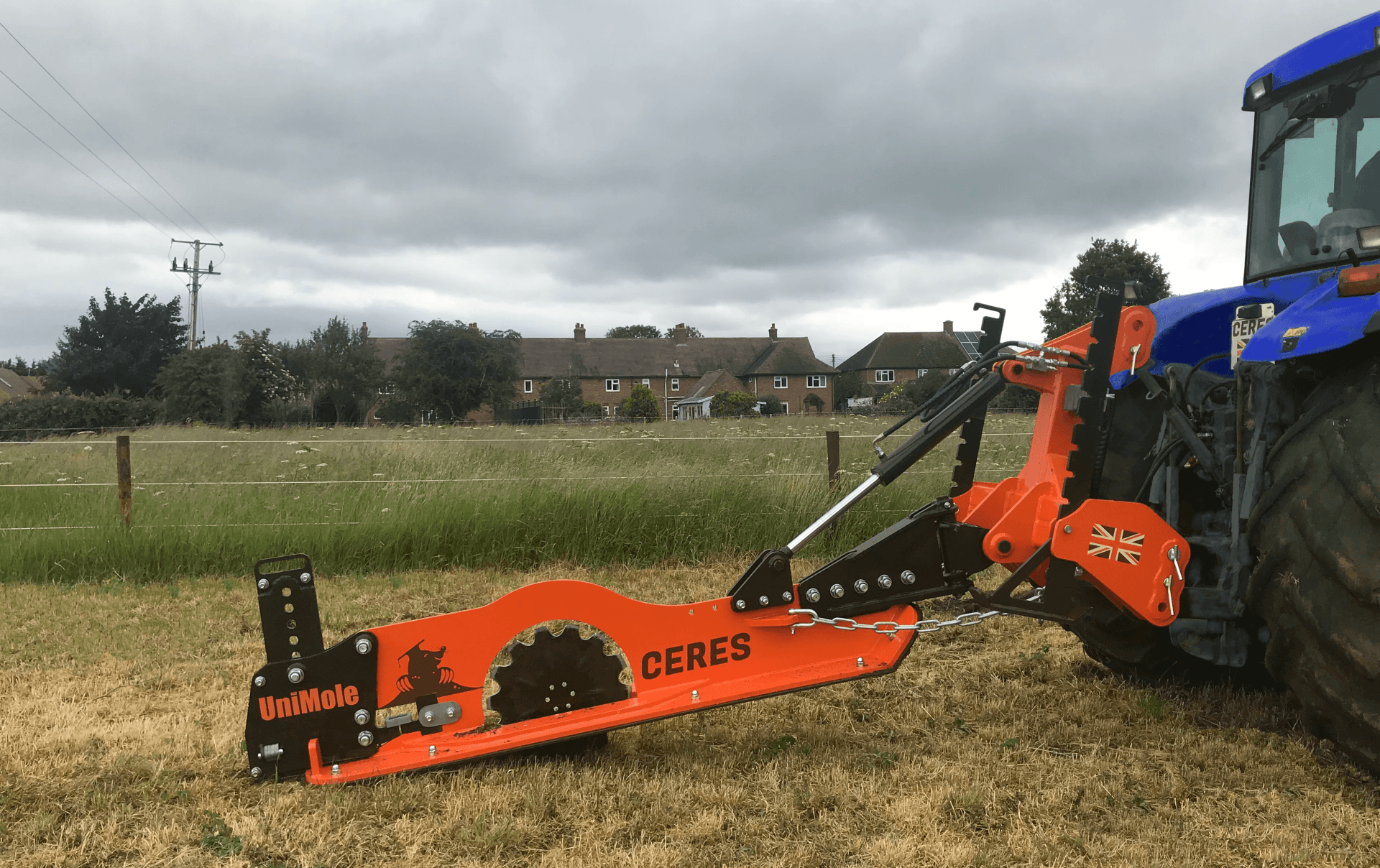

The CERES UniMole Mole Drainer has been developed over several years to bring you the best of both worlds, from a traditional trailed beam mole plough combined with the speed and manoeuvrability of a mounted. A large beam, coupled with its unique ground departure system, creates minimal disturbance, while at the same time the UniMole offers unrivaled longevity of the machine as well as of the mole drain itself.

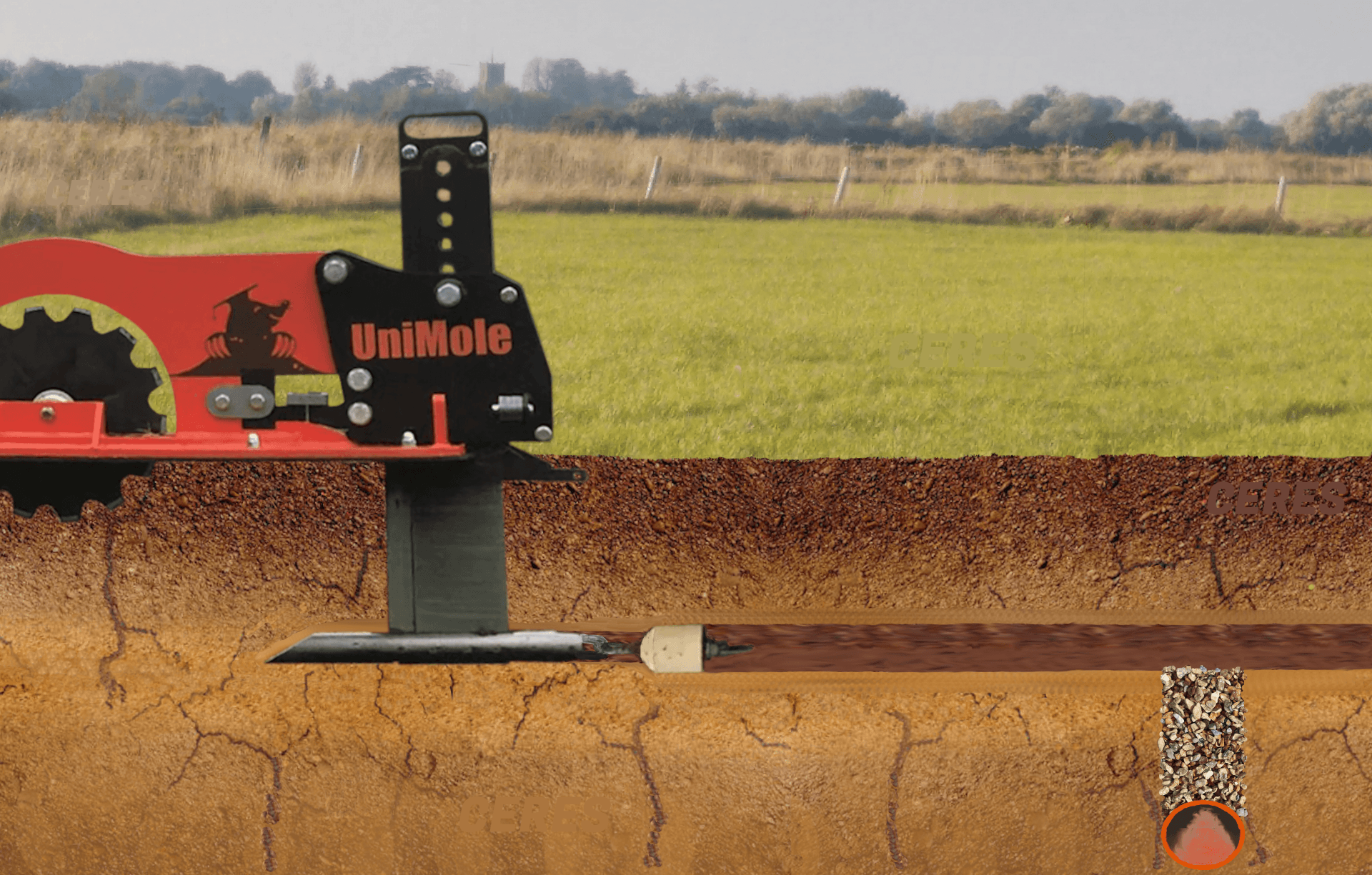

The UniMole's unique hydraulic system is simple to operate. When in work, the tractor spool should remain in float to allow the beam to sit comfortably on its work. Extracting the leg from the ground imposes very little stress on the tractor, by just raising the lift-arms which allows the ram to extend automatically and the leg, bullet and expander to ride out, reducing heave and disturbance. This saves forcing the foot out of the ground, as well as pneumatic shock common with trailed machines. Smooth re-entry to work is easily achieved by lowering the lift-arms; the ram will automatically contract allowing the bullet to draw itself to its pre-determined depth. The hydraulic system is protected by a diverter valve which prevents overloading.

The CERES UniMole Mole Drainer has been developed over several years to bring you the best of both worlds, from a traditional trailed beam mole plough combined with the speed and manoeuvrability of a mounted. A large beam, coupled with its unique ground departure system, creates minimal disturbance, while at the same time the UniMole offers unrivaled longevity of the machine as well as of the mole drain itself.

The UniMole's unique hydraulic system is simple to operate. When in work, the tractor spool should remain in float to allow the beam to sit comfortably on its work. Extracting the leg from the ground imposes very little stress on the tractor, by just raising the lift-arms which allows the ram to extend automatically and the leg, bullet and expander to ride out, reducing heave and disturbance. This saves forcing the foot out of the ground, as well as pneumatic shock common with trailed machines. Smooth re-entry to work is easily achieved by lowering the lift-arms; the ram will automatically contract allowing the bullet to draw itself to its pre-determined depth. The hydraulic system is protected by a diverter valve which prevents overloading.

The CERES UniMole Mole Drainer has been developed over several years to bring you the best of both worlds, from a traditional trailed beam mole plough combined with the speed and manoeuvrability of a mounted. A large beam, coupled with its unique ground departure system, creates minimal disturbance, while at the same time the UniMole offers unrivaled longevity of the machine as well as of the mole drain itself.

The UniMole's unique hydraulic system is simple to operate. When in work, the tractor spool should remain in float to allow the beam to sit comfortably on its work. Extracting the leg from the ground imposes very little stress on the tractor, by just raising the lift-arms which allows the ram to extend automatically and the leg, bullet and expander to ride out, reducing heave and disturbance. This saves forcing the foot out of the ground, as well as pneumatic shock common with trailed machines. Smooth re-entry to work is easily achieved by lowering the lift-arms; the ram will automatically contract allowing the bullet to draw itself to its pre-determined depth. The hydraulic system is protected by a diverter valve which prevents overloading.

The innovative design of the beam incorporates a centrally-mounted 560 mm diameter serrated disc, which has ample clearance to avoid the build-up of unwanted trash and debris, preventing the conventional clogging of the disc within a small channel. The lead edge of the beam is designed to push residue aside. The critical purpose of the beam is to maintain an even pressure over the top of the bullet, preventing premature lift and shatter, and allowing the expander to create an even force to consolidate the subsoil; at the same time, it leaves an open slit from the leg to allow air circulation to dry out the consolidated substrate, giving the mole a far greater longevity. Most modern mole ploughs do not keep pressure over the bullet, which causes ground disturbance, heave, lift and premature fissures, which are exacerbated by the expander, thus reducing consolidation and increasing the chance of mole collapse and slit closure.

The innovative design of the beam incorporates a centrally-mounted 560 mm diameter serrated disc, which has ample clearance to avoid the build-up of unwanted trash and debris, preventing the conventional clogging of the disc within a small channel. The lead edge of the beam is designed to push residue aside. The critical purpose of the beam is to maintain an even pressure over the top of the bullet, preventing premature lift and shatter, and allowing the expander to create an even force to consolidate the subsoil; at the same time, it leaves an open slit from the leg to allow air circulation to dry out the consolidated substrate, giving the mole a far greater longevity. Most modern mole ploughs do not keep pressure over the bullet, which causes ground disturbance, heave, lift and premature fissures, which are exacerbated by the expander, thus reducing consolidation and increasing the chance of mole collapse and slit closure.

The innovative design of the beam incorporates a centrally-mounted 560 mm diameter serrated disc, which has ample clearance to avoid the build-up of unwanted trash and debris, preventing the conventional clogging of the disc within a small channel. The lead edge of the beam is designed to push residue aside. The critical purpose of the beam is to maintain an even pressure over the top of the bullet, preventing premature lift and shatter, and allowing the expander to create an even force to consolidate the subsoil; at the same time, it leaves an open slit from the leg to allow air circulation to dry out the consolidated substrate, giving the mole a far greater longevity. Most modern mole ploughs do not keep pressure over the bullet, which causes ground disturbance, heave, lift and premature fissures, which are exacerbated by the expander, thus reducing consolidation and increasing the chance of mole collapse and slit closure.

The CERES Mole Plough embraces the latest steel technology by using Hardox 450 to increase its lifespan and reduce downtime. Hardox 450 is a specially developed abrasion-resistant steel with a nominal hardness of 450 HBW, designed as an industrial, hard-wearing material, giving up to four times the wearing life of mild steel. The full length skid, the leg and the linkage inserts greatly benefit from the use of Hardox as an exclusive and standard feature. Depth control is easily altered with a single bolt, using the spanners which are supplied and conveniently stored on the headstock. The leg maintains the same geometry during adjustment, removing the need for altering pitch with wedges, packers or screw adjusters, and saving time when moving from field to field. The leg is also protected by an easily replaceable shear link, available in two sizes.

The hard-wearing ceramic expander is another standard feature, which can freely rotate on its axis, allowing it to retain its shape throughout wear. The expander has a convenient transport stowing position, to prevent costly and time-consuming breakages.

We at CERES believe that the UniMole offers the best all-round performance, whether on grassland, stubble, pre-worked or in-crop conditions, bringing an over 100-year-old design up-to-date and making it suitable for efficient, modern farming and contracting applications.

Coming Soon

The CERES DuoMole (two leg) and the CERES TriMole (three leg). Both of these machines are at the prototype stage, please contact us or your nearest CERES Dealer to find out more.

The CERES Mole Plough embraces the latest steel technology by using Hardox 450 to increase its lifespan and reduce downtime. Hardox 450 is a specially developed abrasion-resistant steel with a nominal hardness of 450 HBW, designed as an industrial, hard-wearing material, giving up to four times the wearing life of mild steel. The full length skid, the leg and the linkage inserts greatly benefit from the use of Hardox as an exclusive and standard feature. Depth control is easily altered with a single bolt, using the spanners which are supplied and conveniently stored on the headstock. The leg maintains the same geometry during adjustment, removing the need for altering pitch with wedges, packers or screw adjusters, and saving time when moving from field to field. The leg is also protected by an easily replaceable shear link, available in two sizes.

The hard-wearing ceramic expander is another standard feature, which can freely rotate on its axis, allowing it to retain its shape throughout wear. The expander has a convenient transport stowing position, to prevent costly and time-consuming breakages.

We at CERES believe that the UniMole offers the best all-round performance, whether on grassland, stubble, pre-worked or in-crop conditions, bringing an over 100-year-old design up-to-date and making it suitable for efficient, modern farming and contracting applications.

Coming Soon

The CERES DuoMole (two leg) and the CERES TriMole (three leg). Both of these machines are at the prototype stage, please contact us or your nearest CERES Dealer to find out more.

The CERES Mole Plough embraces the latest steel technology by using Hardox 450 to increase its lifespan and reduce downtime. Hardox 450 is a specially developed abrasion-resistant steel with a nominal hardness of 450 HBW, designed as an industrial, hard-wearing material, giving up to four times the wearing life of mild steel. The full length skid, the leg and the linkage inserts greatly benefit from the use of Hardox as an exclusive and standard feature. Depth control is easily altered with a single bolt, using the spanners which are supplied and conveniently stored on the headstock. The leg maintains the same geometry during adjustment, removing the need for altering pitch with wedges, packers or screw adjusters, and saving time when moving from field to field. The leg is also protected by an easily replaceable shear link, available in two sizes.

The hard-wearing ceramic expander is another standard feature, which can freely rotate on its axis, allowing it to retain its shape throughout wear. The expander has a convenient transport stowing position, to prevent costly and time-consuming breakages.

We at CERES believe that the UniMole offers the best all-round performance, whether on grassland, stubble, pre-worked or in-crop conditions, bringing an over 100-year-old design up-to-date and making it suitable for efficient, modern farming and contracting applications.

Coming Soon

The CERES DuoMole (two leg) and the CERES TriMole (three leg). Both of these machines are at the prototype stage, please contact us or your nearest CERES Dealer to find out more.